Technical Product Bulletin

ELECTRICALLY CONDUCTIVE ONE PART LOW COST EPOXY

PRODUCT DESCRIPTION

AA-DUCT AD1 is a single component epoxy, formulated with pure silver powder combined with organic binders and solvents to produce electrically conductive paths, films or patterns over non-conductive substrates.

AA-DUCT AD1 shows slight settling when stored for a long period of time, no caking and will re-disperse to a smooth homogeneous state.

AA-DUCT AD1 formulation produces electrically conductive paths on a wide variety of surfaces including plastics, rubber, cloth, thermoplastic, paper, wood and many others.

AA-DUCT AD1 designed for use in diversified applications as microwave EMI & RFI shielding, in the assembly or repair of printed circuit boards, wave-guides, electronic modules, flat cable, static shielding, connections, and circuitry.

PRODUCT PROPERTIES

| Appearance | Silver |

| Cure Type | Heat cure |

| Benefits | High strength Perfect bond EMI & RFI shielding Wave guides |

| Substrates | Excellent choice for Integrated Circuits, aluminum, copper, magnesium, steel, bronze, nickel, kovar, ceramic, glass, phenolic and G-10 epoxy glass boards. |

| Catalyst | Anhydride |

| Hardness, Shore D | 83 |

| Typical Applications | microwave EMI & RFI shielding, in the assembly or repair of printed circuit boards, wave-guides, electronic modules, flat cable, static shielding, connections, and circuitry. |

UNCURED PROPERTIES

| Viscosity @ 25 °C cps | 6,800 |

| Density gm/cc | 2.35 |

| Silver , % | 70-72 |

| Shelf life | 6 Months |

| Operating Temperature | -45°C to 170°C |

| Pot Life @ 25 °C | 6 months @ 25°C 9 months refrigerated |

CURE SCHEDULE

| 60 min | @ 120°C, 248°F |

| 30 mins | @ 150°C, 302°F |

| 10 mins | @ 175°C, 347°F |

PHYSICAL CHARACTERISTICS

| Sheet Resistivity | 10-12 mΩ/sq |

| Bulk Resistivity | 3x10-5Ω/cm |

| Adhesion Tensile Strength | 1000 N/cm² (1500 lb/in²) |

| Lap shear Strength | 1400 N/cm² (2000 lb/in²) |

| Thermal Conductivity | 0.04J/(cm.s. °C):[0.01cal/(cm.s. °C)] |

| Specific heat | 0.30J/(g. °C) :[0.07 cal/g. °C] |

| Coefficient of Thermal Expansion | 3x10-5 (m/m)/ °C |

| Modulus of elasticity: | 4x10+10 Pa (6x10⁵ lb/in²) |

GENERAL INFORMATION

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

HOW TO USE

- Carefully clean and dry all surfaces to be bonded.

- Apply AA-DUCT AD1 completely mixed adhesive to the prepared surfaces, and gently press these surfaces together. Contact pressure is adequate for strong, reliable bonds; however, maintain contact until adhesive is completely cured.

- Some separation of components is common during shipping and storage. For this reason, it is recommended that the contents of the shipping container be thoroughly mixed prior to use.

- Some ingredients in this formulation provided may crystallize when subjected to low temperature storage. A gentle warming cycle of 52°C for 30 minutes prior to mixing components may be necessary. Crystallized epoxy components do not react as well as liquid components and should be re-dissolved prior to use for best results.

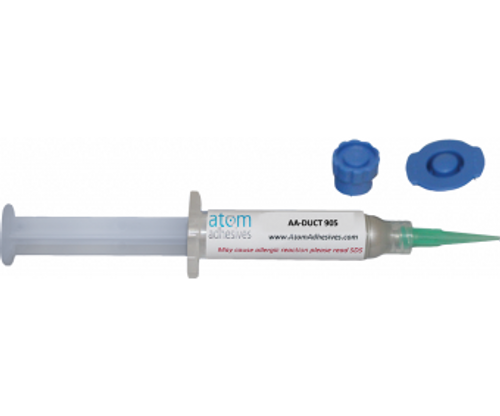

AVAILABILITY

This epoxy can be supplied in various different packages.

Data Sheets: TDS | MSDS available upon request.