Technical Product Bulletin

FOOD AND DRUG APPLICATION EPOXY ADHESIVE

PRODUCT DESCRIPTION

AA-BOND FDA2 is a medium viscosity epoxy resin system specifically developed for medical device applications.

AA-BOND FDA2 is a two-part amber adhesive that has been tested in accordance with USP biological reactivity tests, in vivo, and received Class VI approval.

AA-BOND FDA2 is used and cured at room temperature for bonding, laminating, and repair applications by manufacturers of food preparation, processing, and packaging equipment, as well as manufacturers of catheters, hearing aids, dental products, and other biomedical instruments and devices.

AA-BOND FDA2 provides low permeability to gases and vapors, and good resistance to water, weather, petroleum solvents, lubricants, mild acids and alkalis, and many other organic and inorganic compounds.

PRODUCT PROPERTIES

| Appearance | Amber |

| Cure Type | Room Temperature or Heat cure |

| Benefits |

|

| Mix Ratio by weight | 100:100 Resin to Hardener |

| Operating Temperature | -70°C (-94°F) to +145°C (293°F) |

| Substrates | Most metals, ceramic, glass, and plastics |

| Typical Applications | Bonding, laminating, and repair applications for food preparation, processing, and packaging equipment, catheters, hearing aids, dental products, and biomedical devices |

UNCURED PROPERTIES

| Viscosity @ 25 °C, cps | 14,000 ±2000 |

| Specific Gravity, mixed, gm/cc | 1.11 |

| Reactive solids contents, % | 100 |

| Pot Life | 45 minutes |

CURE SCHEDULE

| 1-4 hours | 65°C (149°F) |

| 24 hours | 25°C (77°F) |

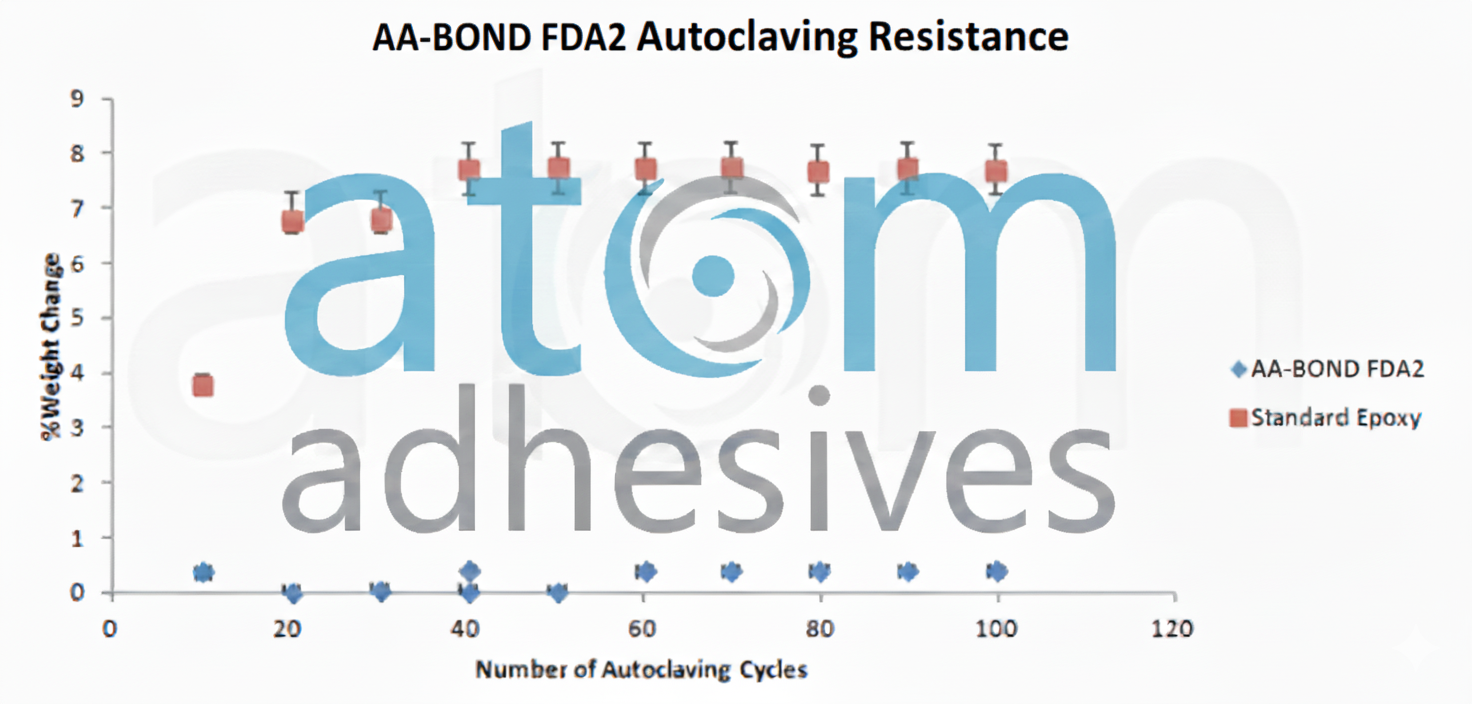

AUTOCLAVE RESISTANCE OF AA-BOND FDA2 EPOXY

Autoclave sterilization is a critical factor in selecting adhesives for medical device applications, as it is one of the most effective and widely used sterilization methods. Atom Adhesives has formulated AA-BOND FDA2 to meet these demanding requirements, offering exceptional durability under repeated autoclave cycles. This USP Class VI approved epoxy has been rigorously tested for biocompatibility and autoclave resistance.

AA-BOND FDA2 samples, cast into discs approximately 2 inches in diameter and 0.125 inches thick, were subjected to up to 100 autoclave cycles, each lasting about 20 minutes at 121°C (250°F) and 15 psi steam pressure. The weight change of the samples was monitored periodically to assess performance. Compared to a standard reference epoxy, which exhibited significant weight gain, AA-BOND FDA2 demonstrated superior resistance to weight change, highlighting its excellent autoclave durability.

CURED PROPERTIES

| Hardness, Shore D | 79 |

| Elongation at Yield | 9.0 % |

| Lap Shear Strength, alum to alum, psi | 1800 |

ELECTRICAL PROPERTIES

| Volume Resistivity, ohm·cm | 1.20e+14 |

| Dielectric Constant | 3.4 @Frequency 1000 Hz |

| Dielectric Strength, kV/in | 420 |

| Dissipation Factor | 0.020 @Frequency 1000 Hz |

THERMAL PROPERTIES

| Glass Transition Temperature (Tg), °C | 54 |

| CTE, linear | 29.4 μin/in-°F @Temperature 68.0 °F |

GENERAL INFORMATION

For safe handling information on this product, consult the Safety Data Sheet, (SDS).

HOW TO USE

- Carefully clean and dry all surfaces to be bonded.

- Apply AA-BOND FDA2 completely mixed adhesive to the prepared surfaces, and gently press these surfaces together. Contact pressure is adequate for strong, reliable bonds; however, maintain contact until adhesive is completely cured.

- Some separation of components is common during shipping and storage. For this reason, it is recommended that the contents of the shipping container be thoroughly mixed prior to use.

- Some ingredients in this formulation provided may crystallize when subjected to low temperature storage. A gentle warming cycle of 52°C for 30 minutes prior to mixing components may be necessary. Crystallized epoxy components do not react as well as liquid components and should be re-dissolved prior to use for best results.

AVAILABILITY

This epoxy can be supplied in many different packages.

Data Sheets: TDS | MSDS available upon request.